Pharma Solutions

With over a century of expertise, ProMach excels in the design, production, integration, and maintenance of cutting-edge pharmaceutical and medical packaging solutions. ProMach's advanced technologies are engineered to address even the most demanding specifications, ensuring minimal downtime, increased productivity, and superior pharmaceutical packaging performance, all while maintaining strict compliance standards.

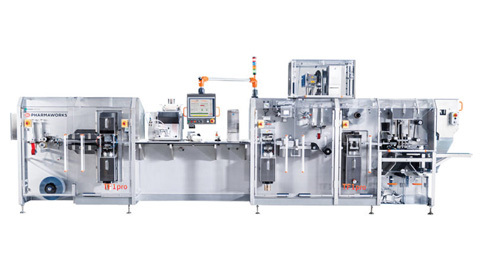

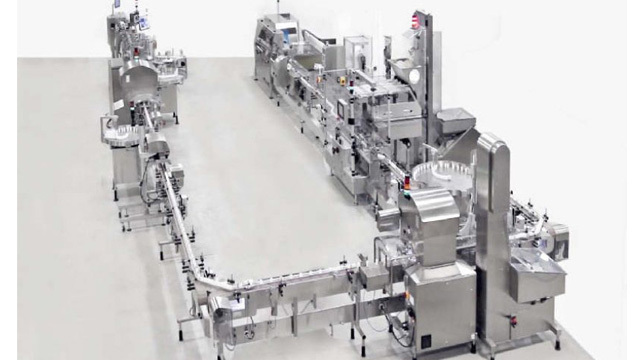

COMPLETE TURNKEY INTEGRATED LINES

ProMach Pharma specializes in meeting the packaging needs of the pharmaceutical industry. The extensive range of packaging technologies and applications offered is complemented by partnerships with other top manufacturers, ensuring that we can supply quality equipment for your packaging line.

What sets ProMach Pharma apart is our comprehensive range of services. From manufacturing to representing key distributed brands and integration, we are a one-stop packaging solutions provider. We offer expert knowledge and support at every stage, from planning to implementation and production.

The ProMach Pharma portfolio includes a wide array of equipment such as

- Unscramblers

- Tablet counters

- Bottle fillers

- Cottoners, Cappers

- Tamper evidence

- Blister packaging

- Labelers, printers, and coders

- End of line equipment

- Liquid aseptic processing/filling equipment

- Washing, sterilization, and decontamination

ORAL SOLID DOSE PACKAGING

ProMach Pharma offers a comprehensive range of solutions for oral solid dosage products. Our product portfolio includes various equipment such as bottle unscramblers, tablet counters, cottoners, blister packaging, cappers, labelers, and digital intelligence tools.

NOTEWORTHY APPLICATIONS

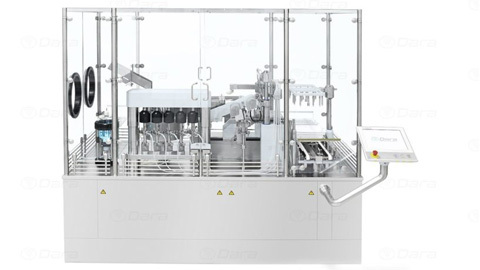

LIQUID FILLING & CLOSING / ASEPTIC PROCESSING

NJM is the exclusive sales representative of Dara Pharmaceutical. With a focus on innovation, Dara Pharmaceutical designs develops, and manufactures a comprehensive range of packaging equipment. Their offerings include washing, sterilizing, filling, freeze-drying, and closing machines, tailored explicitly for vials, bottles, syringes, cartridges, and IV Bags. These machines are designed to process liquid, semi-solid products, and powders in sterile conditions, ensuring the highest safety and reliability standards.

NOTEWORTHY APPLICATIONS

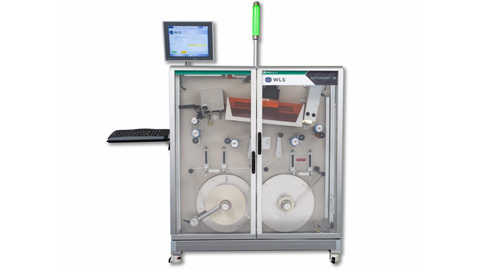

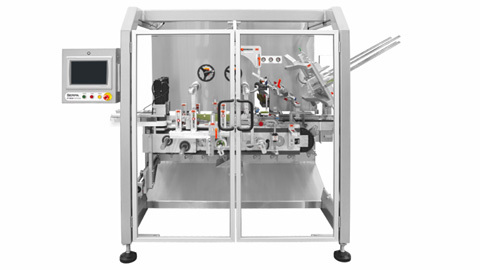

LABELERS, LABEL PRINTERS, AND CODERS

For over three decades, Weiler Labeling Systems (WLS) has been at the forefront of designing, manufacturing, integrating, and supporting advanced rotary and in-line labeling solutions. The company's unwavering commitment to customer satisfaction has resulted in consistently positive feedback regarding the quality and services provided by WLS. Furthermore, by actively engaging with customers and learning from their valuable input, WLS continually expands its product line to introduce new and innovative offerings.

NOTEWORTHY APPLICATIONS

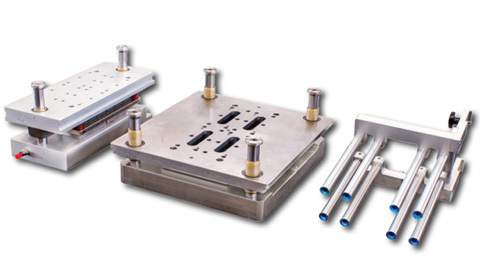

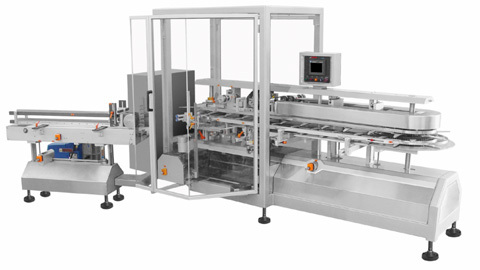

BLISTER PACKAGING

Pharmaworks excels in manufacturing innovative blister packaging systems for the pharmaceutical industry. Thermoforming solutions offer robustness and flexibility, allowing the creation of blister packs for both over-the-counter (OTC) and prescription unit dose pharmaceuticals. Their blister solutions cover a wide spectrum, ranging from semi-automated machines to fully automated systems capable of achieving speeds of up to 600 packages per minute. In addition to core blister packaging machinery, Pharmaworks also provides complementary systems such as feeding, transferring, collating, cartoning, and vision/inspection systems.

NOTEWORTHY APPLICATIONS

SECONDARY PACKAGING

Serpa meets all sanitary and FDA validation requirements, our ergonomically designed packaging equipment is available in both sanitary- and balcony-style construction. Our extensive experience with serialization, multiple insert feeding capabilities, super-efficient/high-speed leaflet feeding as well aspartition placement all add up to high-performance results. Serpa's packaging equipment is designed for easy access, maintenance-friendly operation and offers rapid verified and automatic changeovers.

NOTEWORTHY APPLICATIONS

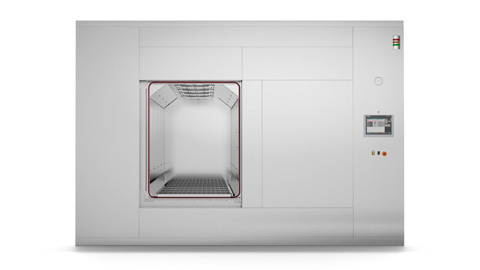

WASHING, STERILIZATION, AND DECONTAMINATION SOLUTIONS

NJM exclusively represents Steelco's Pharma and Biopharma products in North America. Steelco sets a new standard for automated cleaning equipment in the pharmaceutical industry with its comprehensive range of GMP washers. These products feature a modular design and exceptional quality. Steelco's cleaning systems adhere to the latest cGMP guidlines, encompassing design, manufacturing, validation, and documentation. Additionally, Steelco provides complete turnkey solutions for pharmaceutical sterilization processes. Together, NJM and Steelco manage all project phases, ensuring solutions surpass customer expectations.